Bahrain World Trade Center Manama building design, Wind turbines images, BWTC architect

Bahrain WTC Building : Architecture

World Trade Center in Manama : Technical Aspects

post updated 23 June 2025

BWTC spins all turbines for the first time

The Atkins designed Bahrain World Trade Center (BWTC) made history today as the turbines on this pioneering project turned together for the first time.

Bahrain WTC Wind Turbines design:

8 April 2008

Bahrain WTC Wind Turbines News Update

Design: Atkins architects office

The three 29m-diameter turbine blades on Bahrain’s iconic landmark are the first in the world to be integrated on such a scale into a commercial development and are forecast to provide the equivalent of 11-15% of the power for the two towers when fully operational.

“Having all three turbines spinning simultaneously represents an historic achievement for this landmark project and Atkins is excited to have been a major player in turning the original idea into reality” says Simha LytheRao Senior Project Manager for Atkins in Bahrain.

The First Large Scale Integration of Wind Turbines in a Building

Technical Paper (Images + text) about the Bahrain WTC Wind Turbines from Atkins 231207:

Richard F Smith MSc. C.Eng, MCIBSE & Shaun Killa BAS, BArch

Atkins, Middle East, Dubai UAE

Abstract

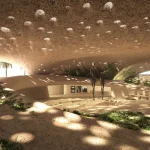

Design illustration of the Bahrain World Trade Center

This paper describes the design evolution of the large scale wind turbines proposed for the Bahrain Trade Center. It gives a detailed description of the wind turbines and how they are controlled demonstrating how several innovative ideas came together were technically validated and produced the design for this unique building.

1. Introduction

The Bahrain World Trade Center forms the focal point of a master plan to rejuvenate an existing hotel and shopping mall on a prestigious site overlooking the Arabian Gulf in the downtown central business district of Manama, Bahrain. The concept design of the Bahrain World Trade Center towers was inspired by the traditional Arabian “Wind Towers” in that the very shape of the buildings harness the unobstructed prevailing onshore breeze from the Gulf, providing a renewable source of energy for the project.

The two 50 storey sail shaped office towers taper to a height of 240m and support three 29m diameter horizontal-axis wind turbines. The towers are harmoniously integrated on top of a three story sculpted podium and basement which accommodate a new shopping center, restaurants, business centers and car parking.

Tapering towers with the three wind turbines

The elliptical plan forms and sail-like profiles act as aerofoils, funnelling the onshore breeze between them as well as creating a negative pressure behind, thus accelerating the wind velocity between the two towers. Vertically, the sculpting of the towers is also a function of airflow dynamics. As they taper upwards, their aerofoil sections reduce.

This effect when combined with the increasing velocity of the onshore breeze at increasing heights creates a near equal regime of wind velocity on each of the three turbines. Understanding and utilising this phenomenon has been one of the key factors that has allowed the practical integration of wind turbine generators in a commercial building design.

Wind tunnel testing (See section 3) has confirmed how the shapes and spatial relationship of the towers sculpt the airflow, creating an “S’ flow whereby the centre of the wind stream remains nearly perpendicular to the turbine within a 45° wind azimuth, either side of the central axis. This increases the turbines’ potential to generate power whilst also reducing fatigue on the blades to acceptable limits during wind skew across the blades.

The specific architectural forms of the Bahrain World Trade Center towers were borne from using the nautical expression of a sail to harness the consistent onshore breeze, potentially to generate energy using wind dynamics, as well as to create two elegant towers for Bahrain, which would transcend time and become one of a kind in the world.

2. Background

Whilst the impetus for this innovative design solution came entirely from Atkins’ Chief Architect, Shaun Killa, the client readily embraced the concept to portray to the world that Bahrain is committed to options that reduce demand on fossil fuel energy reserves and will move urban and building design in desert climates in a more sustainable direction. The complexity of integrating large scale wind turbines in a building structure is not to be underestimated and the client expects a key benefit from this project to be the knowledge and experience gleaned which can then be disseminated to design teams globally.

Like many architects around the world, the Atkins design team in the Middle East has considered design solutions that incorporate sustainability and have investigated the concept of utilising integrated wind turbines on several previous concept designs. The wind climate in the Arabian Gulf with its dominant sea breeze characteristic is conducive to harnessing wind energy and allows designers to move away from the more conventional omni-directional solutions and consider uni-directional wind turbine options that in many respects, lend themselves to the large scale integration in buildings.

Research by Atkins has shown that the large scale integration of turbines into buildings mostly fails because of the excessive cost (up to 30% of the project value) associated with the adaptation of the building design, and also as a result of high research and development costs for special turbines. From the outset this project had as its primary basis of design the utilization of conventional technologies and the development of a built form that would be sympathetic to receiving wind turbines. The premium on this project for including the wind turbines was less than 3% of project value.

So with the benefit of a favourable wind climate and a design philosophy that minimised turbine R&D / building costs, Atkins, with a team of world leading technologists moved forward with the design and addressed the key issues of:

1 Producing technically viable solutions;

2 Balancing energy yield / benefit with investment

3. Environmentally Responsive Design

This building is not intended to be a low carbon emission solution by European and other world-wide standards. However, aside from the wind turbines, it does include a number of other design features that are of interest and reduce carbon emissions when compared to other buildings in the Middle East. These are summarised below:

1. Buffer spaces between the external environment and air conditioned spaces to reduce sol air temperature and reducing conductive solar gain;

1a. Deep gravel roofs in some locations that provide kinetic insulation;

2. Significant proportion of projectile shading to external glass facades;

3. Balconies to the sloping elevations with overhangs to provide shading;

4. Where shading is not provided to glazing, a high quality solar glass is used with low shading co-efficient to minimise solar gains;

5. Low leakage, windows;

6. Enhanced thermal insulation for opaque fabric elements;

7. Dense concrete core and floor slabs presented to the internal environment in a manner that will level loads and reduce peak demand with associated reductions in air and chilled water transport systems;

8. Variable volume chilled water pumping that will operate with significantly less pump power at part loads than conventional constant volume pumping;

9. Low pressure loss distribution for primary air and water transport systems that reduces fan and pump power requirements;

10. Total heat energy recovery heat wheels of fresh air intake and exhausts to recover ”coolth” from the vitiated air and recover it to the fresh make up air;

11. Energy efficient, high efficacy, high frequency fluorescent lighting

12. Dual drainage systems that segregate foul and waste water and allow grey water recycling to be added at a later date;

13. Connection to the district cooling system that will allow an order of magnitude improvement on carbon emissions since in Bahrain efficient water cooled chillier are not allowed due to water shortage, whereas the district cooling solution will involve sea water cooling / heat rejection and much improved levels of energy conversion efficiency;

14. Reflection pools at building entrances to provide local evaporative cooling;

15. Extensive landscaping to reduce site albedo, generate C02 and provide shading to on grade car parks;

16. Solar powered road and amenity lighting.

4. Building Integrated Wind Turbines

4.1 Wind Analysis

Three wind turbines have been integrated into the building to generate electricity. Horizontal axis wind turbines are normally pole mounted and turn to face the direction of the wind thus maximizing energy yield. The practical application of such turbines to buildings in variable direction wind climates is therefore very difficult.

The majority of architectural studies deploying building-integrated, horizontal axis turbines deploy the principle of a fixed turbine as in the case of the Bahrain World Trade Center. Development for vertical axis wind turbines is encouraging and of course they benefit from the advantage of being truly omni-directional. However, at the time of design development for this project, large scale proven vertical axis turbines were not available for building applications.

The fixed horizontal turbine suffers the drawback of only being able to operate with wind from a limited azimuth range, if problems with blade deflections and stressing through excessive skew flow are to be avoided. From the outset of this project, the shape of the towers has been designed to capture the incoming wind and funnel it between the towers.

Extensive wind tunnel modelling that was latterly validated by CFD modelling. have shown that the incoming wind is in effect deflected by the towers in the form of an S-shaped streamline which passes through the space between the towers at an angle within the wind skew tolerance of the wind turbine. Engineering predictions show that the turbine will be able to operate for wind directions between 270° and 360°, however, caution has been applied and turbine predictions and initial operating regimes are based a more limited range of between 285° and 345°. At all wind directions outside of this range the turbine will automatically adopt a ”standstill” mode. It is no coincidence that the buildings are orientated to the extremely dominant prevailing wind.

The funnelling of the towers has the effect of amplifying the wind speed at the turbine location of up to 30%. This amplification, in conjunction with the shape of the towers (larger effect at ground) and the velocity profile of the wind (lowest at ground) has the effect of balancing the energy yield to the extent that the upper and lower turbines will produce 109%and 93% when compared to 100% for the middle turbine.

4.2 Wind turbine system components and control

The fixed, horizontal axis wind turbines on this project comprise the following key components:

1 Nacelle: including enclosure with gearbox, generator, cooling system and associated control systems

2 Rotor

3 Bridge

4 Control, monitoring and safety systems

5 Electrical Building Interface

4.2.1 Nacelle and Rotor

The nacelle is the term used for the cowling containing the gearbox, brake, controls, etc. and in addition, there is the rotor.

Wind turbine details

Nominal electrical power generated: 225kW

Power regulation: stall

Rotor diameter: 29m

Rotor speed at full load: 38 rpm

Air brake: centrifugally activated feathering tips

High speed mechanical brake: fail safe type disc brake

Low speed mechanical brake: caliper type

Generator: closed, 4 pole asynchronous induction, 50Hz

Yaw system: fixed yaw

Cut in wind speed: 4m/s

Cut out wind speed: 20m/s (5 minute rolling average) – reduced from 25m/s for this application

Maximum wind speed for blades: 80m/s (any direction) Class IV hurricane = >69m/s

Nacelles have been designed to sit on top of the bridge, rather than within it, to portray the functionality of the turbine. The turbine is a simple and robust “stall controlled” type. The stall control is a passive way of limiting power from the turbine. The rotor blades are bolted onto the hub at a fixed angle and the profile has been designed to ensure that the moment the wind speed becomes too high. It creates turbulence on the leeward side of the rotor blade and prevents lift, stalling the blade so that the power output stabilizes at a maximum output.

The full power of about 225kW will be achieved at 15 to 20m/s depending on air density. In the event of extremely high wind speeds under operating or standstill modes, the tip of the blade extends by centrifugal force and rotates to act as a self regulating governor brake, through the exertion of a drag force.

For this project, nacelles are a conventional design with some enhancements to suit the desert application and to increase the structural safety. The guidelines in the Danish code of practice1)2) has been used for increasing the structural safety to “High Safety class”. Conventionally, Eurocodes would be referenced, but they do not address high safety classifications.

Each nacelle operates independently and is not affected by the failure of another nacelle.

4.2.2 Bridges

A key part of the design is the determination of loads on the rotor, through the nacelle and thence onto the bridge and buildings, so that structures can be analyzed for strength and fatigue.

The load calculation approach for this project has been made by the bridge design consultant in conjunction with the wind turbine manufacturer using a specially adapted version of the industry-best wind turbine simulation tool, “Flex4” 3). The tool has been adapted to take account of the influences of the buildings and the bridges.

A total of a 199 different load cases has been modelled for each turbine and validating calculations or operational processes prepared to theoretically demonstrate that the turbine and bridge would survive without excessive fatigue. During the early stages of operation, this theoretical analysis will be validated and appropriate adjustments made to the operating regime that may increase or decrease energy yield.

The bridges are ovoid in section for aerodynamic purposes and are relatively complex structures because they incorporate maintenance free bearings where they connect to the buildings to allow the towers to move 0.5m relative to each other. In addition, the bridges that span 31.7m and support a nacelle with a mass of 11 tonnes have been designed to withstand and absorb wind induced vibration and vibrations induced by both an operating and “standstill” turbine.

Analysis by the bridge designer has been undertaken to estimate the natural frequency of the bridge and to ensure it does not conflict with the frequency of exciting vibrations of itself or the building. Further precautions are included in the design to allow the bridge to be damped, if in practice vibrations are found to be problematic during commissioning. These precautions include the facility in the design to add spoilers to the bridge and to adjust the tuned mass damper.

The bridge is a shallow V-shape in plan (173º) to take account of blade deflection during extreme operating conditions and to afford adequate clearance and thus avoid blade strike. Under these conditions, blade clearance to the bridge of 1.12m is achieved. The worst scenario is with blade tips extended giving a factor of 1.35 safety margin, and under this condition adequate clearance is still achieved. Additionally a laser blade position monitoring system is incorporated that will set the turbine to standstill if deflections become excessive.

4.2.3 Control, monitoring and safety

Turbine control, monitoring and safety is delivered through three systems:

1 Wind turbine control system (WTCS) that directly controls and monitors the turbines;

2 Extended wind turbine monitoring system (EWTMS) that is a separate monitoring system developed for this project;

3 Building monitoring system (BMS).

The WTCS is an industrial quality control system that has been specifically evolved to control and monitor wind turbines. It is robust and reliable and as well its control and monitoring functions, it is able to shutdown turbines safely in the event of adverse climatic conditions or due to other factors that will threaten life-safety or turbine life.

It is an on-line system that allows operators anywhere to gain access to the operating data and grant those with appropriate authorisation control of the turbines. It has an in-built independent, emergency, safety surveillance system that will monitor possible faults in the turbine and the immediate turbine operating environment and bring it to a standstill, if required. This system overrides the electronic control system. The WTCS obtains data relating to the turbine operating environment via the BMS. Finally the WTCS retains significant data regarding turbine operation and provides tools for analysis.

Data obtained by WTCS

Wind direction (masts in front and on top of buildings); Building electrical consumption demand;

Building maintenance system operational; Manual start, stop and emergency stop.

Bridge access opening;

For this specific application where safety is crucial the WTCS fully integrates the special control and monitoring functions.

Special Data obtained by WTCS

Wind speed at bridges; Accelerometers at front wind turbine bearing and in bridges – threshold function;

Free wind direction near ground level and at top of the building – redundant function; Blade distance from bridge – threshold function.

The EWTMS is a project bespoke system that works in conjunction with WTCS to provide monitoring and calibration of the control system operational limits required for this specific application. In total the EWTMS has 43 additional sensors.

EWTMS monitoring and calibration functions

Wind speed at bridges & ground level;

Free wind direction near ground level and at top of the building;

Ambient temperature and atmospheric pressure;

Blade strain;

Transmission torque strains; High speed gear shaft speed;

Accelerometers at front wind turbine bearing;

Accelerometers in bridges;

Distance between blades and bridge;

Rotor rotational position.

In the event of a control system failure the turbine is brought to standstill by the tip brake working in conjunction with the hydraulic brake through a power fail – failsafe mechanism.

The BMS is the building monitoring system and this will be used as a means of providing connectivity from remote sensors to WTCS and EWTMS.

4.2.4 Electrical building interface

Each nacelle has a 225kW nominally rated, 400V, closed, 4 pole induction, 50Hz, asynchronous generator that is connected to a generator control panel inside each tower. From each generator control panel, separate low voltage feeders connect to the interfaces on the main low voltage switchboard at three substations. These substations supply electricity to the landlord areas of the World Trade Center development.

Generators are designed to start and run in an asynchronous mode and in parallel with the electricity authority’s grid, but at this stage it is not possible to export electricity to the electricity supply authority in the event of a surplus being available.

In the event of an outage or reduction in voltage/frequency from the board’s power supply the turbines will be shut down.

The length of the LV feeders from the generator control panels to the building electrical system interface points, required careful study in order to avoid excessive voltage drop and to ensure there were no problems with harmonics and voltage disturbances. Extensive dynamic simulation studies were carried out by the turbine manufacturers’ electrical specialist partner company to ensure compliance with relevant IEC standards.

5. Design Validation through Safety, Availability, Reliability and Maintainability (SARM)

The design has been validated using a SARM analysis by Ramboll with Atkins-Science and Technology in a review role.

Issues addressed by validation team:

Remote sensor viability

Power outage impact

Electricity board acceptance

Cooling system availability

Maintenance viability

Rain water thrown off blades

Exciting vibrations

Bridge resonant frequency

Construction tolerance –v- bridge resonant frequency

Bridge vortex shedding

Source / sink coincidence

BMS reliability

Lightening strike

Blade loss

Tip break off

Blade penetration

Blade / bridge strike

Blade fall

Climate Sand ingress

Bird strike

Turbine operation outside of azimuth range

Availability

Reliability and maintainability

Operability and durability

Previous performance of proposed turbine

Project specific operating and control strategy

Unusual flow and fatigue life

Dirt build up on blades

Galloping vibration at standstill

Maximum twisting moment for a blade

Noise emitted from blades / generator

Shadow flicker

Reflection of blades through windows

Electromagnetic interference.

Electrical flicker

Electrical harmonics

6. Energy Yield

The projected energy yield from the turbines taking into account wind and availability data is summarised below. This amounts to between 1,100 and 1,300 MWh per year and will amount to approximately 11% to 15% of the office tower’s electrical energy consumption. In carbon emission terms this equates to an average of 55,000 kgC (UK electricity basis). These figures are conservative. Since this is a world first and because wind turbines have not been placed 160m above ground level and between buildings, the yield may even be higher.

Energy Yield

Turbine # 1 340 to 400 MWh/year

Turbine # 2 360 to 430 MWh/year

Turbine # 3 400 to 470 MWh/year

7. Final Lesson

It should be appreciated that this was a fast track design and construction programme and that the integration of large scale wind turbines into a building has involved extensive research and development by probably some of the most capable specialists available. It is recognized that the initial phases of operation of this project will be the final part of the learning curve. During this stage significant monitoring and fine tuning are required in order that full potential of this innovative application may be properly realized and understood.

References

1) Danish code DS409. “Code of Practice for the Safety of Structures”

2) Danish code DS412. “Code of Practice for the structural use of steel”

3) Flex4 : Simulation of wind turbine dynamics. Load analysis software used by Ramboll/Norwin and originally developed by the Technical University of Denmark

Acknowledgements

The decision to include this technology has not been taken lightly and has been the subject of rigorous design and validation. Building design (all technical disciplines) was by Atkins – Middle East. The wind turbine and bridge design and manufacturing specialists involved are Ramboll Denmark A/S – Consultants, Norwin A/S – Turbine Manufactures, Elsam Engineering A/S – Power Generation. Wind Tunnel Testing was done by BMT and Atkins, DE2 and Atkins, Science & Technology have executed high level technical reviews.

Bahrain World Trade Center : main page on the WTC towers in Manama.

Bahrain WTC Wind Turbines images / information from Atkins

Bahrain World Trade Center architects : Atkins

Location: Bahrain World Trade Center

Architecture in Bahrain

Contemporary Bahraini Architectural Projects

Bahrain Building News – architectural selection below:

Pearling Site, Muharraq

Design: Valerio Olgiati

image Courtesy architecture office

Museum and Entrance to the Pearling Path

The site contains ruins that form part of the UNESCO Pearling Path. The entire building functions as the entrance to the cultural heritage and the foyer for the medina.

Amwaj Villa, Manama

Design: Moriq

photograph : Riyaz Quraishi

Amwaj Villa in Bahrain

This was a single family home which we designed in an upmarket locality of Bahrain called Amwaj Island. The Clients wanted modern architecture and well defined interior areas and high in design value with as less of decoration as possible. The architecture practice planned the home on 3 levels, the lower to have the lounges/dining/kitchen and no beds at all.

Bahrain Marina Masterplan, Manama

Design: Benoy

image Courtesy architecture office

Bahrain Marina Masterplan Development

Benoy, the international, award-winning Architecture, Masterplanning, Interior and Graphic Design firm, is thrilled to announce the first phase of the Bahrain Marina Development in Manama, Bahrain.

Nomas Towers Bahrain – also by Atkins

Buildings / photos for the Bahrain WTC Wind Turbines Building page welcome